Steffes Weld Academy Spotlight

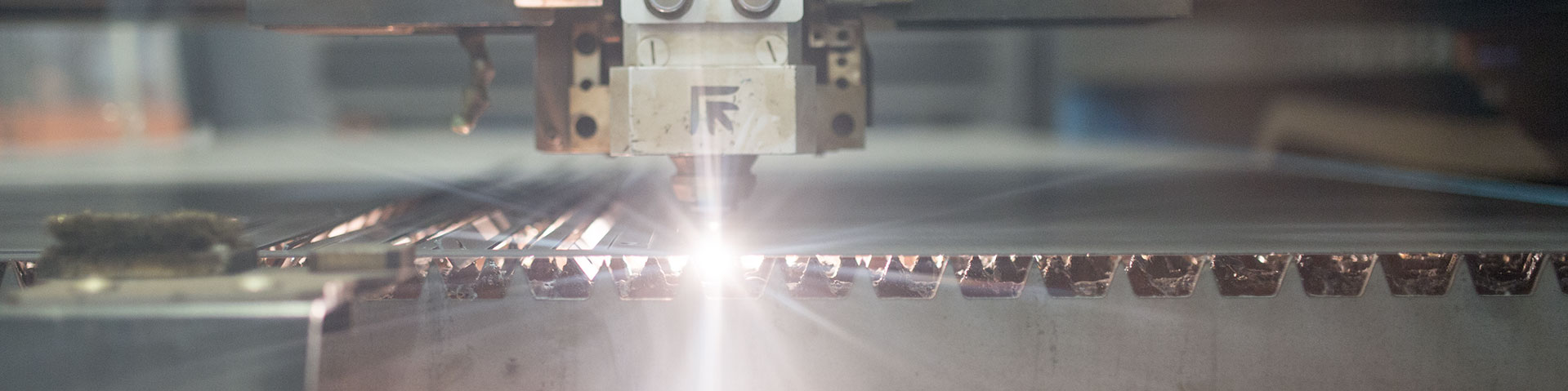

It’s your first day on the job, you step onto the manufacturing plant floor to the hum of machines and occasional bright flashes of light. You’re filled with anticipation and excitement, ready to begin your new role but uncertain of how to be successful. Our team at Steffes recognized this learning curve many new employees were experiencing, especially new welders, and took action to launch a customized training program in 2018.

The Steffes Weld Academy was developed to train new welders about our production and safety specifications to help them acclimate to Steffes work standards. Prior to offering this program, new hires were onboarded in an inconsistent manner which resulted in a lengthy training process to try and understand how to be successful in their new role.

The Steffes Weld Academy was developed to train new welders about our production and safety specifications to help them acclimate to Steffes work standards. Prior to offering this program, new hires were onboarded in an inconsistent manner which resulted in a lengthy training process to try and understand how to be successful in their new role.

Now, this hands-on program ensures everyone is being trained to the same welding standards, procedures, and blueprints to deliver a quality weld. Once a welder feels comfortable with their training, they must successfully pass a weld assessment to move to production. On average, a new hire could spend the first day or two of their employment in Weld Academy going over Steffes procedures and quality standards. Since implementation, the Weld Academy has improved employee confidence and efficiency. Welders are now equipped with comprehensive knowledge they need to succeed in their role.

Welders can complete Weld Academy level tests to advance to higher positions.

These levels include Level I: entry level weldments, Level II: advanced weldments with higher quality expectations, or Level III: certified pipe and vessel welding.

There are also opportunities for tech savvy welders to become robotic weld operators and programmers if the passion is there.

Another Weld Academy graduate stated: “I like that Steffes is willing to teach their employees how to weld different types of things.”

Since the launch, 100 employees have successfully completed Steffes Weld Academy training. 54 team members have graduated from our Dickinson program and 46 team members have graduated from the program at our Grand Forks facilities. Both locations have 3 certified program trainers.

Since the launch, 100 employees have successfully completed Steffes Weld Academy training. 54 team members have graduated from our Dickinson program and 46 team members have graduated from the program at our Grand Forks facilities. Both locations have 3 certified program trainers.

Steffes corporate culture prioritizes safety, and the design of our welding facilities are no exception. Weld cells are ergonomically designed with safety in mind to help welders produce the highest quality welds as comfortably as possible. Steffes invests in top of the line, innovative equipment from Lincoln Electric and constantly tests new products to ensure welders are able to operate in the safest, most efficient way possible. All welding is done indoors in brightly lit weld cells with great air quality and clean workspaces.

If you are interested in learning more about welding at Steffes, visit our Careers page.