STEFFES SPOTLIGHT: Greg Nickel

Manufacturing has changed in many ways throughout the past 35 years, and Greg Nickel has had a front row seat to many of the changes and technological advances implemented in Steffes’ manufacturing processes.

Manufacturing has changed in many ways throughout the past 35 years, and Greg Nickel has had a front row seat to many of the changes and technological advances implemented in Steffes’ manufacturing processes.

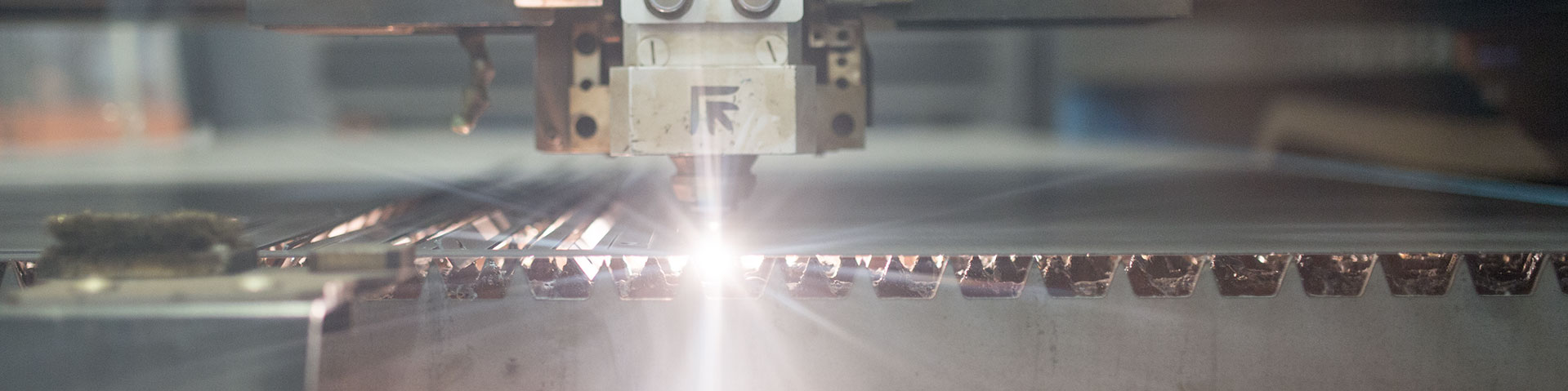

Greg began his career at Steffes in 1986 as a general floorhand helping wherever he was needed. From running the dyes for manufacturing snowmobile skis to running the shear and eventually operating the first laser installed in the early 2000’s.

“It was really exciting, I was an operator on it,” said Greg. “It did so much, it was really neat to see the first laser come in.”

From 2000 to 2005 he ran the first 3500 watt prima laser, which has since been replaced with the 5000 watt laser in use today, and eventually moved to operating the brake where he continues to work as a machine operator at our Dickinson facilities.

Greg has been part of many changes and growth during his time at Steffes, making hopper bottom grain bins and snowmobile skis in the early days to playing a role in the expansion of our oil & gas product line and now supports all products ranging from our Electric Thermal Storage products to Contract Manufacturing.

“I’ve seen a lot more computers, CNC machines have really come in… everything is CNC now,” said Greg. “I’ve seen a lot of technology come in and make it (manufacturing) faster and more accurate.”

A typical day in his role as a machine operator involves bending parts on the brake for different product lines. One day he may be working on parts for our Contract Manufacturing products and the next he may be helping to manufacture parts for ETS products while running his 135 ton brake.

“They just turn me loose on my machine and let me go… I know how to make good parts and they’re correct,” said Greg. “Someone has to get it done, someone has to do the manual labor to get the parts out the door.”

Greg runs the brake and works closely with 2 other team members to keep production running to prevent bottlenecks, filling in on the weekends when they are needed to ensure products are manufactured in time for delivery.

“My favorite part is just working with good people… North Dakotans, we understand one another. We work hard and we’re honest with one another,” said Greg. “The people are fun to work with and as the years went by the pay went up, the benefits improved, things just kept getting better over time and the company kept getting bigger.”

Greg’s favorite Steffes company event is the annual Holiday party and the summer company picnic. He enjoys when the company looks back on the year and how it went.

In his free time, Greg enjoys being outdoors, especially in the summer months when he can enjoy the nice weather by camping or just enjoying the sunshine in his backyard. He also loves grilling a good ribeye steak. A fun fact about Greg is that he is currently working on obtaining his hand license for his radio technician class to earn his A.M. radio license after passing a rigorous exam. He enjoys studying the materials during his lunch and breaks at work.